Since the invention of computer-aided design (CAD) in the early 1960s, it has become much easier for product designers to design sheet metal components and parts for different applications. But one challenge that has remained constant is the need to find a suitable manufacturing method to create these designs.

CNC machines offer high accuracy and meet tight tolerances, but they come with the drawback of high cost and material wastage. While 3D printing eliminates this material wastage challenge, product designers have limited metal options when it comes to 3D printing. A popular manufacturing method that has been helping product designers create cost-effective sheet metal parts accurately is cold forging.

But what exactly is cold forging, and what makes the process so special? This article explains the cold forging process and provides some of the key calculations product designers must know about cold forging.

Industrial forging presses are being used to manufacture sheet metal parts. Source: Nataliya Hora/Adobe Stock

Cold forging is a metal shaping and manufacturing process that plastically deforms and compresses a piece of raw material under a punch and a die. The process typically takes place at room temperature rather than at higher temperatures like hot forging.

Unlike in conventional machining, where sections of a workpiece are removed to form desired parts, cold forging deforms existing material into the desired shape. This makes it possible to achieve high-speed production, little to no material wastage, and strong end products due to work hardening of the raw material.

Depending on the type of dies used, cold forging can be of two types:

In open-die forging, the raw material is placed between two flat dies with no precut profiles and that do not enclose the workpiece. The compressive force from the dies deforms the metal piece till the desired shape is formed.

![Open-die forging. Source: Banerjee/CC [SA] [2.5]](https://insights.globalspec.com/images/assets/176/17176/Forging_2.png) Open-die forging. Source: Banerjee/CC [SA] [2.5]

Open-die forging. Source: Banerjee/CC [SA] [2.5]

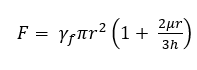

The forging force required for this cylindrical workpiece (in Figure 2) can be calculated using:

Where:

Yf = flow stress of the material (Pa)

A = cross-section area of the workpiece (m2)

r = instantaneous radius of the workpiece (m)

h = instantaneous height of the workpiece (m)

μ = coefficient of friction between the die and the workpiece

Some of the advantages of open-die cold forging operation on a workpiece include improved strength and fatigue resistance. However, keep in mind that products obtained from open-die cold forging operations usually need some secondary machining (or refining) to achieve desired dimensions and tolerances. It might not be an ideal forging method for creating intricate and precise parts.

Closed-die forging is a forging process that involves placing the workpiece between one or more custom-shaped dies. When compressed and deformed, the workpiece flows to fill the shaped-die cavity (shown in Figure 3), taking the cavity’s shape and forming the desired end-product. Excess material, also called flash, from this forging process is subsequently trimmed off.

Closed-die forging. Source: sanya_zx9r/Adobe Stock

Closed-die forging. Source: sanya_zx9r/Adobe Stock

Compared to open-die cold forging, closed-die cold forging operations produce parts with a better surface finish, superior mechanical properties and tighter tolerances. The process eliminates the need for additional post-machining operations common in open-die cold forging operations. It is the ideal method for large-scale production.

The forging force required to perform a closed-die cold forging operation can be calculated using:

![]()

Where:

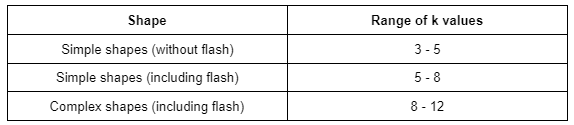

k = multiplying factor

Yf = flow stress of the material (Pa)

A = projected area of the forging, including the flash (m2)

The range of k values for different kinds of shapes has been provided in Table 1.

Table 1. Range of k values for closed-die forging

Table 1. Range of k values for closed-die forging

Consider a scenario where there is a need to cold forge a cylindrical part having a projected area (with flash) of 0.03 m2 and flow stress of 500 MPa. If the k value for the simple part is obtained to be 6, then the forging force would be 90 MN.

While this article provides useful information about cold forging, there still exist many other considerations and factors that affect the quality of cold-forged parts. Product designers are advised to reach out to manufacturers to discuss their project requirements, including dimensions, tolerances and lead times, among others.

聯(lián)系人:Rob

微信:18666076565

手 機(jī):18925189619 (In Mandarin, Cantonese & English)

電 話:020-31190575

郵 箱:sales@gzyuto.com

公 司:廣州粵拓機(jī)電設(shè)備有限公司

地 址:廣州市番禺區(qū)橋南街蜆涌村市南路653號102

網(wǎng)站: shareluxe.cn